-

Content count

292 -

Joined

-

Last visited

Posts posted by Knuckledragger

-

-

1) Would you suggest the yellow Tygon 4040 be an anual replacement as well?

2) Im replacing ALL of my uel lines, how many feet do I need.

3) Did you shop it out? Do mind sharing an Internet link to the cheapest supplier if you have it handy. It'd help us lazy folks out.

1) I replace all fuel lines if they've been on the plane over a year. This includes clamps, ties, etc. IN addition to the lines the mechanical aspects of the fuel delivery system need the annual attention. The line itself will probably "last" a lot longer, but the mechanical connections, rubs, etc are where the wear that will cause a failure is happening.

3) I buy only pulse line (7/16" OD X 1/4" ID) and prefer clear line over yellow or other colors. The color, yellow, blue, red, makes little difference in the quality of the line as long as its the tygon/tygothane. I buy from this guy: http://www.ebay.com/itm/121370316373?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

-

You might be blocking a lot of the exit opening out of the bottom of the cowling and also looks like you had to remove the lip that creates the low pressure area. You may have to open it up more and add another lip.

This might be a stretch but you have incredibly low EGT's.

That can indicate either a too rich condition, or too much load. if you are in a too much load condition, you might be able to pull the pitch back a bit, bring the EGT's up where they belong, and in doing so produce less heat because the engine won't be working so hard.

+1 to both of these.

-

I believe the pitch is set at 12.5 degrees static to limit rpms at 6200

Its ok to set the static rpm a little higher to reduce the prop load, to see if that helps temps. As others have said, seal the cheek rads and make sure you have a good lip pulling the air out the bottom of the cowl (and through the rads). Also consider adding a kitfox belly rad inline with the cheeks. Mine (a 582) had this but ran too cool so I took it out. You may have just enough extra juice to need the extra cooling capacity.

-

I have one of these too. 503, 6 blade IVO with clutch. Support is pretty much non existant. I bought my avid from the guy who owns aero venture. Very nice people but focused on filling orders on their rendition of a Searey.

Let's compare notes. I'm in the process of rebuilding the landing gear with fresh bungees, new wheels and tires and fresh caulk.

1 person likes this -

Porsche 914. Maybe 1974?

1 person likes this -

I should probably just delete it. The Internet has gotten so rude. Keyboard courage prevents people from having a little fun I guess.

The gist of the video: there is a big plywood silhouette cutout in the shape of Bigfoot stood up in the brush where only a low flying plane or nearby boat might see it. We flew over until we found it and took video and had a great laugh. I slowed the video down and highlighted the "Bigfoot" in adobe premiere and posted for others to get a laugh too. The effect was to draw out the worst in folks. Oh well, we had fun. :)

-

-

Your low visibility pics give me the willies! I took off into some fog waiting for me just beyond the runway end the other morning and had a total white out until ~1200' - that was only a little over a minute. I can't imagine what it must be like for you up there!

That lodge and the nature around it looks so peaceful. I don't think my little Avid would make it all the way there before spring though...

1 person likes this

1 person likes this -

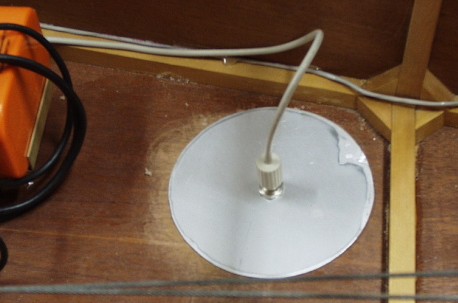

I found this picture on the internet.

So this type of ground plane would not be effective because it is not grounded to the aircraft frame?

Isn't the coaxial cable itself grounded through the transponder?

Most likely. The ground plane is bonded to the transponder via the cable shielding - that's the important part. If the return for power feeding the transponder is bonded the same way (most likely is) then the ground plane is bonded to the air frame.

-

Love the sound of that turbo!

-

My buddy Frank and I found Bigfoot today!

1 person likes this -

-

What is the RPM of the Sagami motor?

-

I think they're great looking too and would be quite nice with some sanding and perhaps spar urethane. However, with smaller grips I could get 1/2-3/4" extra control travel either side - which would come in handy when doing forward slips on final.

-

Merry Christmas!

PS, where can I get one of those bottomless backpacks?

-

-

I run 89 ethanol free moo gas & Penzoil. I'm looking to switch to Amsoil once I find a local source for it.

-

Did you buy the Jersey avid?

Yes, that's it in the pic.

Looks like hammer and chisel or new tubes and leave the wood grips intact on the old toobs. Heat didn't seem to work.

-

-

-

Big thanks to Chris Bolkan and Mark Sires for spending time with me on the phone today!

-

I just read on the EAA forums, guys with similar wing top pin hole issues came with this solution: Use a carefully applied vacuum source to put negative pressure inside the tank while allowing resin to be sucked back into the hole. It will find its way into the leak and seal it. Hmmm...

-

I called Kitfox today. They said the airfoils are different enough that their tank wont work in my speedwing. I'm running out of ideas here....

I'm pulling my hair out trying to figure out what to do about my leaking tank. The leak is on top of the wing. It just showed up as a pinhole in the fabric about 1/3 of the way back from the leading edge. Prior to seeing the stain that formed on the fabric, I noticed that I was using 5-6 gals of fuel per hour. I imagine that the fuel is being vented out by the low pressure air flowing over the wing.

-

582 Fuel requirements

in Two Strokes

Posted

Where are you buying 98 pump gas?