-

Content count

122 -

Joined

-

Last visited

Posts posted by Good old number 29

-

-

The previous owner of my Kitfox had performed a similar stunt with the trailer. Fortunately for me, it didn’t damage steel, like your incident. Still, it broke a wood stringer and punched a nice hole in the bottom of the fuselage.

-

Pushing to cover the wings before I go to Africa. I haven’t done anything to the plane in the last couple weeks. Work has been a bother, and a lot of things have just been distracting me any time I try to work on the plane. Don’t get me wrong. I like my job, and I am thankful to have it, but it’s a complicated work situation. Today, my wife came out to my cold, crowded, mess of a shop, and helped put fabric on. That was a first for both of us. I’m pretty happy with the results.

I did install double extra rib bracing. Yes, redundancy. See, there was bracing in the second rib bay on the right wing, for the six gallon tank. I removed the tank, replaced the anti drag tube with a full length one, and added rib braces to that first bay. I left them in the second bay. Then, anticipating the new, 13 gallon tanks, I installed rib braces on the third rib. When I install the wing tanks, those extra braces will go away, and I’ll already have the ones I need, outboard of the wing tank, without having to pull the fabric back farther.

The hanger rib brackets are great. The weak hanger ribs and the false ribs on the leading edge are the two worst design issues on the Kitfox. The brackets really stiffened up the ribs. Who thought that gluing 1/8” plywood on edge was the best way to make an airfoil? Hanging the flaperons off 1/4 plywood that’s out in the weather? I shouldn’t complain. It just seems like there was a better solution.

So, it’s coming together nicely. Icould have been done, but it was good to focus my attention on ther things, and not get burned out. I still don’t have the crankshaft bearings.

-

-

Hmm. Somebody forgot to take pictures, today.

I had a great trip to Girdwood, with my wife, and did some hiking around Alyeska over the weekend. Totally off topic, but these are the things in life that really matter. I’m just thankful to God for all the goodness in my life. I’ve been wanting to say how proud I am of my daughter, too. She beat four girls in 100yd backstroke, in high school swimming. With no legs. She lost both legs above the knee in an accident on Christmas, 2014. It’s pretty awesome to have seen her come so far. Ski season is coming up, and she’s excited about that. Two of our boys got in a motorcycle wreck, a week or so, ago. They’re okay. The young one is proud of it.

So, today I realized that the rivets spec’ed in the service bulletin are not the right length for attaching the reinforcing brackets to the flaperon hanger ribs. After I had them in place, and covered with adhesive. Good thing it comes off with paint thinner. The length specified was only the thickness of the material, and didn’t account for proper protrusion. Put them on my list and bought the rivets without thinking any more about what length they ought to be. I did get the tubing for the wing rib braces and anti-drag diagonal brace in place, where the wing tank was. I got the false ribs that Jim sent. Still have to stick them on the other wing. I might need to make another run to Anchorage to get the right rivets, so I can cover the wings. Eh. Maybe MARC has them in Soldotna. I should be so lucky. I got the “band-aid” riveted in place on the rear spar. It looks good. Still can’t believe he put so many holes in the spar.

I’ve crossed a lot of things off my list. Down to three dozen. Realistically, it’s about half a dozen. False ribs, covering, engine reassembly, prop, odds and ends. I’ve been thinking that I need to stick some lights on it.

2 people like this -

Got my “band-aid” cut and drilled, flaperon brackets fitted and drilled, and false ribs attached on the right wing. I drilled the rivets and removed the skylight out of the turtle deck. My wife texted me, two hours ago, about all the things she did in the house. I’d say that I think she’s great, but I think that’s missing the point.

1 person likes this -

The answer is probably that my 503 doesn’t need carb heat. I have read a few reports of carb icing on Rotax 2 strokes, so I was considering it because of that. I’ve never had carb icing on the many snowmachines I’ve ridden, but it’s usually colder, and you’re banging around a bit (at least I do), and on and off the throttle, so not much chance for it there. You’re in the same area. Have you ever had any issue with it? I figured I’d put the wrap on the muffler and get some cab heat, and it wouldn’t be too much more effort to tee in carb heat.

-

I have one of these that came with the Kitfox 1 I bought. The muffler is already tight to the lower cowl, so I might need to do some modifications to install it. I have in mind a way to also use it for carb heat. I’ll post an update on it, once it’s installed, and I’m up and flying.

-

Not mentioning any names, but those holes were made by an A&P in Soldotna. I could hardly believe that anyone would do that, but I got the receipt for his work, from the previous owner, when I bought the plane. That same mechanic replaced the fan belt, and the fan blew up right after takeoff, on the test flight. They did a quick turnaround and dead stick landing on the runway. The owner did the repair work after that incident.

My plan has been to do exactly as AKFlyer suggested. I got the doubling plate cut and rolled, yesterday. I’ll make radiused cuts in the ends, so it doesn’t have a hard, straight edge making a break point. Then, I’ll bond it to the spar with epoxy, and pin it with Cherrymax structural rivets. Twenty three holes in the spars in one bay, to attach a wing tank cover, with dozens of holes in the ribs and cap strips, too. Why, oh why, would anyone do that? Nineteen holes in the rear spar, and four in the front. I mean, I can fix it, but that is seriously ridiculous. Oh, and when I got it, that wing tank still leaked.

-

Thanks, Jim. Getting closer to closing the wings back up

I got my flaperon hanger rib reinforcing brackets made today. I’m taking some time to relax, this evening, and I’ll get them fitted tomorrow.

I’ll get the old props boxed up and sent off tomorrow, too, if I can. I need to take a little time to square away the wiring, too. I wish those crank bearings would show up. Several items have been back ordered, and I’m waiting for them to ship.

-

That’s a good point about being able to grind down the shaft diameter. I didn’t try anything like that, because I wasn’t exactly sure about piston stroke, and I didn’t want to come up short on my seals. I haven’t bled the brakes since I reinstalled them, but I know I have at least half an inch. I actually needed an inch and a half, though. How I have it now isn’t much different geometry than when I got it, and the brakes worked okay. The angle on the pedals is really nice, now. Feet make even contact on both rudder and brake pedals, and just a little toe to give it brakes.

-

-

-

Yeah, those holes are not what I would have done to attach a wing tank cover. He put a bunch of holes in the ribs and cap strips, too. The front spar has four, 1/4” holes with threaded insert rivets in them. I guess I’ll leave the riveted holes on that one, but plate the back spar. There was a bracket riveted there, to which the cover plate was screwed, following a repair to the tank. Not how I would have done it. My plan is to cut a reinforcing plate, with radiused corners, so it doesn’t have hard edges, and rivet it to the spar, using the same holes. I can use the old bracket as a template to line up the holes. Rivet and bond it to the spar.

-

I got the new windshield installed, this afternoon. Replaced the brake pads, packed the wheel bearings, and put it back on the wheels. I’m still looking at how I want to change the brake brackets. It looks like the master cylinders were replaced with longer units than original. The mounting brackets had been moved further up, reducing leverage, but weren’t moved far enough to get the right angle for the brake pedals, as relating to the rudder pedals. The brakes did work okay. You just couldn’t stay off them, using the rudder. Someone with a buzzbox stuck them on with 6011, as evidenced by the welds. I cut the tabs off, and ground off most of the built-up weld. I haven’t quite talked myself into moving the bracket clear to the top of the pedal to see if it works, but I think I’ll give it a shot. Not a lot of good options on it.

-

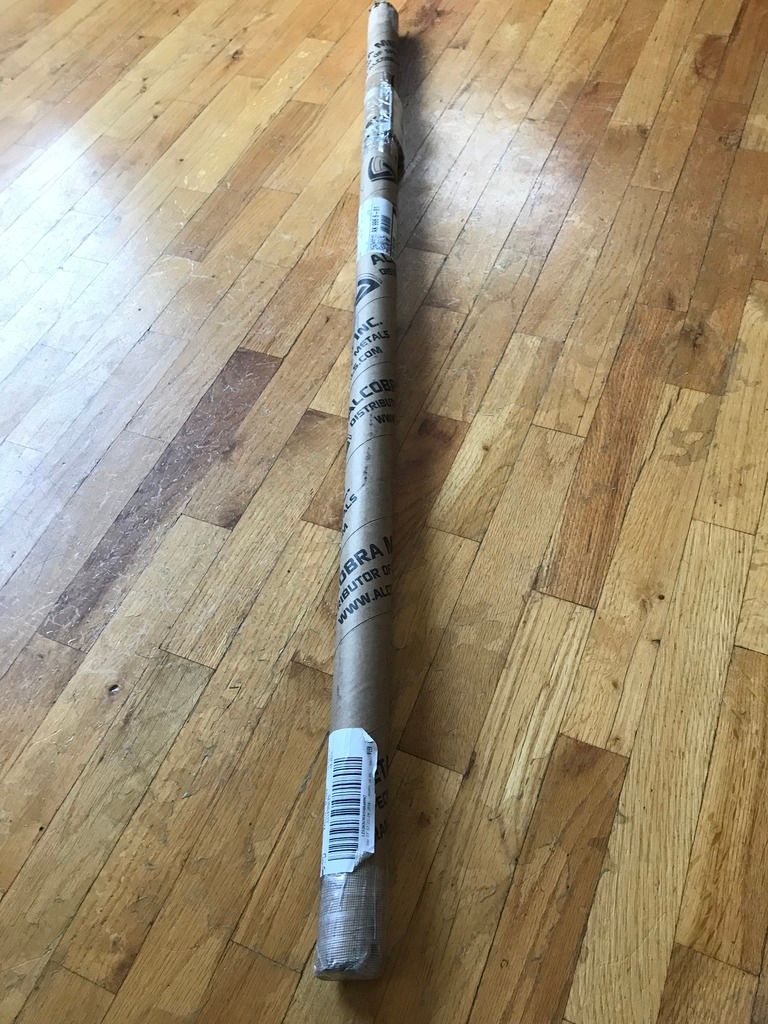

It’s been a busy few days, but I managed to make progress in spite of it. Got the other wing spars cleaned up and primed. Pretty happy with the results. I pulled off the shortened drag/anti-drag tube that was installed in the bay next to the old wing tank. The tubing to make a new and proper replacement is in the mail. Should be here tomorrow. I also pulled off the brackets that were used to mount the sheet metal wing tank cover. I’ll need to rivet a bandaid in its place. The big thing that I managed to do lots of, is spend money. Nine hours of driving, on Friday, netted me the fabric, all the coatings, including paint, the sheet metal to make the flaperon reinforcement brackets, and handfuls of other parts and tools. I also picked up a new intercom. The only other big thing I might buy is a prop. I’ve been leaning toward getting a Power Fin.

I’m getting close to the point that I can re-cover the wings. Still waiting on the main bearings, so I can finish the motor.

I sold my motorcycle, tonight. I hated to see it go, but it’s for a good cause. I already sold my little skiff to help finance this project.

And, still having problems posting pics. Seems like smaller ones do okay, but I don’t like messing around, trying to make them little enough to post.

In light of the corrosion issues with my spars, I HIGHLY recommend that you prime the bare aluminum in the wings before assembling and covering them. Proper prep is key to a good coating, and it is well worth it. Considering that my plane is thirty years old, the bare aluminum spars did pretty good. But, if they had been properly primed, it would have saved me a lot of time and work, and wouldn’t have had any corrosion, at all. In fact, I might not even have needed to pull the fabric, if the oxidation hadn’t caused the false ribs to let loose. When I cleaned the spars, prior to priming, I found that some of the epoxy (Hysol or Scotch-Weld) fastening the ribs to the spars, had blistered. I found this after I cleaned up the first wing. There was some blistering evident on the second wing, prior to paint prep. I cleaned all of the blistered adhesive away from the ribs prior to priming, and was more careful with the MEK when I cleaned up the second rib, in case that had been a factor.

-

Here is a link to my original posts in the other forum, in case anyone wants to see the full story.

http://www.teamkitfox.com/Forums/showthread.php?p=77511&posted=1#post77511

-

It’s placarded as being 414 lb. empty. My scale, adding 8% for known inaccuracy, had it at 400, minus the battery and wing tank. I’m going to shoot for making it that 400 lb, 52 hp Rotax 503 powered Kitfox of legend. Then I’ll add the wing tanks so I can actually go places.

-

Yes, that hanger rib is highly questionable. It’s the inboard one on the left wing. Looks to me like it was installed with that warp in it, or at least some pressure that direction. The discoloration is from moisture, but it’s not soft. It does have a little split in that kink. I’ve been kicking around different ideas on the repair. My uncle is coming to take a look at it, to help make the reinforcing brackets. He’s a retired sheetmetal worker, and flies a C-180. It’s great that he’s willing to help, since he has a sheet metal brake and a bit of expertise that I don’t have. I’m going to do all of the flapperon hanger ribs. It might be good to make the brackets longer than specified, to give a little more strength.

-

Jim,

I need to replace at least five false ribs. Some were repaired or warped, so I could use as many as ten. I just got word that the wing tanks won’t be ready for six weeks, instead of 3-4 weeks from when I ordered them. I’ve decided to proceed without them, so I can get the covering done before it gets super cold. Maybe next year I’ll do the fabric on the fuselage when I fit the tanks.

-

-

-

The skis are aluminum. They’re not bad, but they’re quite a bit heavier than the wheels, tires, and brakes. I could make a pair that is bigger, for more flotation, but also lighter, without sacrificing strength. I’d also turn up the tips further. Comparing them to Buckchop’s fiberglass skis, his are lower profile. These are about the same height as with the 20” tires. I like that it gives it a bit more prop clearance. I’ve seen picture somewhere of Kitfox skis built with a tubular aluminum framework, that looked lighter.

-

TJay, thanks for the info on tank weight. 10 pounds isn’t bad, and that extra capacity will be great.

-

Allen, if I get it going in a month, I’ll come and help you. I’m a firm believer in having goals that are hard to reach. Anyway, I can work on it as much as I need to for the next 35 days. No problem getting it done in 300-400 hours. I do have it all disassembled, but three weeks ago, I was taxiing it around the yard, so it’s not like it was a basket case. Just needed some TLC, and I’m trying to be thorough.

Bringing a Kitfox 1 back to life

in Kitfox I

Posted

I am in Anchor Point. Pretty happy with my purchase. I did get it for quite a bit less than he was asking. I saw on here where someone had commented on the ad. He had two, but he sold the other before I saw the ad, so I don’t know what it was. When I was a kid, my neighbor was building a Model 3 in his garage. I got to check it out a little, and watched the promo video. He never finished it, but it still had an effect on me. He said he sold it to a guy in Soldotna who finished it and painted it red. You might see it around, too. Yes, mine is coming along pretty good. I’ve put ore into it than I paid, including two new wing tanks and a prop that I could have done without, but I think I’ll be glad I got them. And I couldn’t have bought the package for this price. Well, if you factor in the time I put into it, I could have bought one that was already flying, but I like doing the work myself, and I’m glad I got to do it.